Leading manufacturer of high-quality wheels, having produced over 10 million wheels under VIA, JWL, and JWL-T standards over the past 35 years. as ORIGINAL EQUIPMENT MANUFACTURER (OEM) wheels for automobile factories in Thailand and around the world Its technological leadership qualities set it apart. with Thailand's only production technology, such as forming with a Flow-Forming 3-axis system The world's most recent generation, electrolytic inductive paint (EDP), and many more, so that production potential can be increased. To be fully controlled, the company has reached the level of 1,000,000 rings per year while adhering to ISO 9001, IATF 16949, ISO 14001, and BS OHSAS 18001 standards.

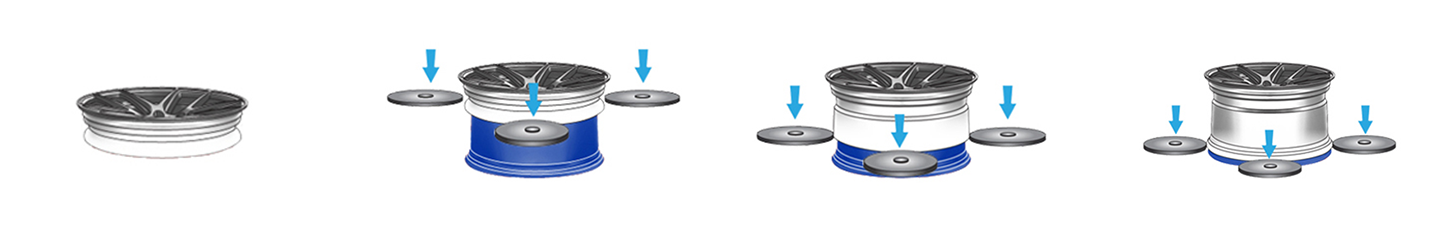

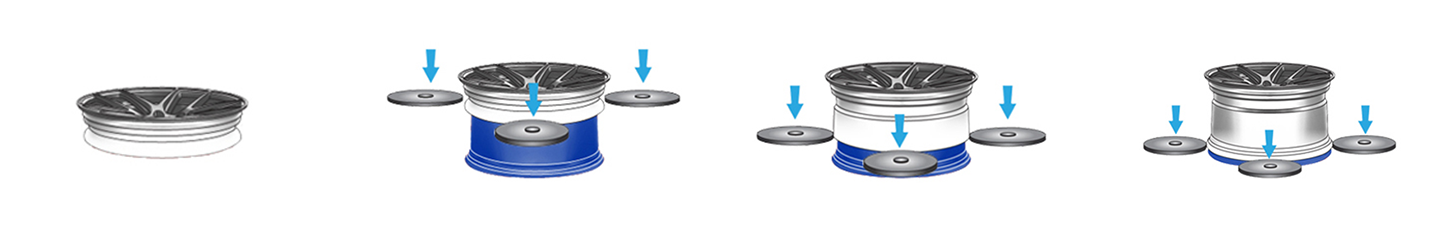

Flow-Forming 3-axis rotation 3VF (Three Vertical Flow-Forming) production system for high-efficiency alloy wheels. Germany The only machine in Thailand from Yachiyoda, a manufacturer of alloy wheels, ORIGINAL EQUIPMENT (OEM). Alloy wheels of international quality for automobile assembly plants The production capacity is 1,000,000 rings per year, both at home and abroad